CHARTERED ENGINEERING & CALIBRATION COMPANY

- …

CHARTERED ENGINEERING & CALIBRATION COMPANY

- …

Welcome to Chartered Engineering & Calibration Company (CEC) SL Ltd

PETROLEUM ENGINEERING IDEAS

MECHANICAL ENGINEERING SPECIFICATIONS

FABRICATION OF PETROLEUM TANKS

Creating innovative Engineering portfolios that enhance the way we live and work.

-----

Chartered Engineering and Calibration Company - The Chief Industrialist in Modern Engineering

About CEC

Through Developing Engineering Excellence, Your Challenge Our Expertise

Innovative Engineering Techniques

The Chartered Engineering and Calibration Company (SL) Limited (CEC) was officially established in Sierra Leone, West Africa, has a highly qualified, experienced and competent team of professional engineers, business professionals and technicians with proven

records in asset sustainability, project and operation management.

We have a proven record of service delivery with reliability, leveraging on the professionality of our specialists to satisfy our clients. We are global in our reach through collaboration with partners in the sub regions and beyond and at the same time can deliver locally .At Chartered Engineering & Calibration Company (CEC), we specialize in creating innovative and sustainable engineering elements that exceed our clients' expectations. Our team of experienced experts are dedicated to bringing your vision to life.

Exceptional Quality

We are committed to delivering exceptional quality in every project we undertake. Our attention to detail and commitment to excellence ensure that every work is executed with precision and care.

Client-Centric Approach

Our client-centric approach means that we prioritize your needs and goals throughout the design process. We strive to create spaces that not only meet your requirements but also enhance your lifestyle.

Our Services

Your challenge our expertise

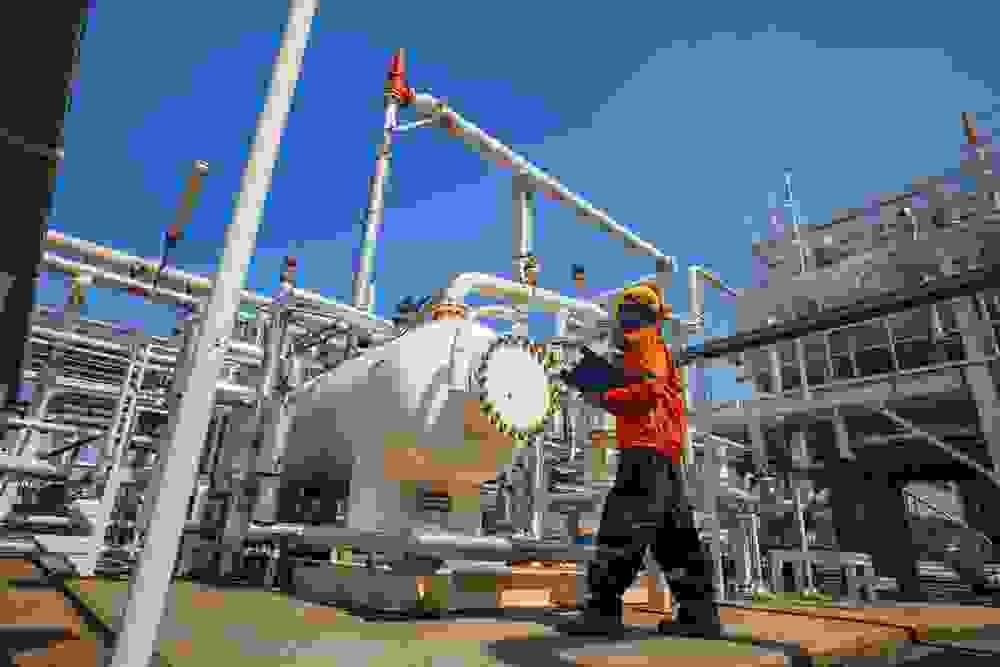

Gas Vessel Inspection Operation And Handling

Vessel inspection operations involve a systematic examination of a ship's structure, systems, and equipment to ensure it meets safety and operational standards. These inspections are crucial for preventing

accidents, ensuring regulatory compliance, and optimizing vessel performance.

KEY ASPECTS OF VESSEL INSPECTION OPERATIONS

Safety and Risk Prevention:

Inspections aim to identify and address potential hazards, such as hull integrity issues, machinery malfunctions, or system failures, before they escalate into accidents or environmental incidents.

Regulatory Compliance:

They ensure adherence to international maritime regulations, including

SOLAS (Safety of Life at Sea), and prevent costly disputes related to

vessel condition.

Operational Efficiency:

Inspections help optimize vessel performance by identifying inefficiencies and potential breakdown risks, leading to improved fuel efficiency and reduced maintenance costs.

TYPES OF INSPECTIONS

Various types of inspections exist, including:

Annual Surveys: Focus on major systems to ensure compliance and safe operation.

SIRE (Ship Inspection Report Programme) Inspections: Used by

oil companies to assess tanker safety and operations.

Vessel Safety Checks: Performed by organizations like the Coast Guard Auxiliary, focusing on required safety equipment.

Pressure Vessel Inspections: Specifically for pressure vessels,

ensuring their integrity and safe operation.HANDLING VESSEL INSPECTIONS

Proper handling involves

Preparation:Ensuring the vessel is clean, dry, and free of any

contaminants that could hinder the inspection or endanger personnel.

Standardized Procedures:Using detailed checklists and procedures to ensure consistent and thorough inspections.

Reporting and Follow-up:Documenting findings, addressing critical issues, and implementing corrective actions.

Utilizing Technology:Employing inspection apps and other tools to streamline the process and improve data management.

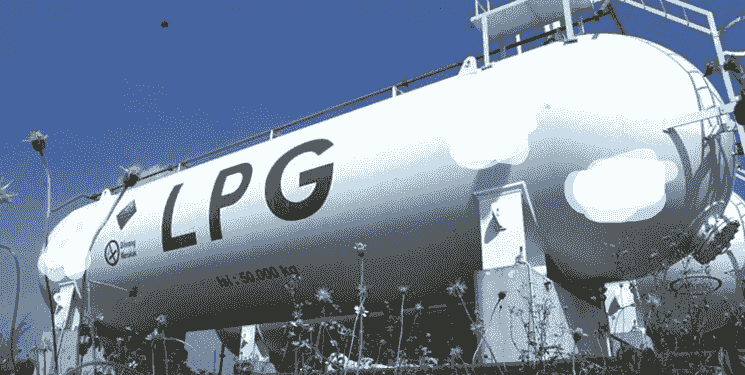

Liquid Petroleum Gas (LPG) Operation

Liquid Petroleum Gas (LPG) operates by being stored and transported as a liquid under pressure but vaporizes into a gas when used. This vaporization process is key to its function as a fuel source.

LPG is a hydrocarbon mixture, commonly propane and butane, and is stored in pressurized cylinders or tanks. When a valve is opened, the liquid LPG expands into a gas, which can then be used for various applications like heating, cooking, and powering vehicles.

Here's a more detailed breakdown:

1. Storage and Transportation:

LPG is stored and transported as a liquid under pressure. This is achieved by keeping the LPG at a temperature below its boiling point, which is around -42°C. This pressure liquefies the gas, making it more convenient to store and transport in cylinders or tanks.

2. Vaporization:

When the valve on a cylinder or tank is opened, the LPG is released into a lower-pressure environment. The liquid LPG expands and vaporizes into a gas. This vaporization process requires heat, which is drawn from the sorrounding environment.

3. Usage:

The gaseous LPG is then used as a fuel source for various applications. Common uses include heating, cooking, hot water, and powering vehicles.

4. Safety Considerations:

LPG is flammable and can be explosive if mixed with air within the flammable range. Proper ventilation is crucial when using LPG indoors to prevent dangerous gas buildup. LPG cylinders should be stored and handled with care, following safety guidelines to prevent leaks and

accidents.

Liquid Natural Gas (LNG)

Liquified Natural Gas (LNG) is natural gas that has been converted into a liquid state by cooling it to a very low temperature, typically around -260° Fahrenheit (-162° Celsius). This process reduces its volume significantly, making it easier and more cost-effective to transport and store, especially over long distances where pipelines are not feasible.

WHY IS LNG IMPORTANT?

Enables Long-Distance Transport:

LNG allows for the transport of natural gas to markets that are too far from producing regions to be connected by pipelines.

Provides Energy Security:LNG can diversify energy sources and ensure a reliable supply of natural gas, especially when renewable energy sources fluctuate.

Potential for Future Growth: Global LNG demand is projected to

increase, driven by economic growth in Asia and efforts to reduce

emissions.

Flexibility: LNG can fill in gaps when renewable energy sources are

intermittent.

Construction of Tanks

We offer comprehensive tank construction services, including conceptualization, planning, and construction documentation, to bring your vision to reality.

Construction of Petroleum Pipeline Network

Our petroleum pipeline fabrication services are tailored to create functional and aesthetically pleasing spaces that reflect your unique style and personality.

Construction of Bridges

From inception to completion, our bridge building project management services ensure that every aspect of your project is carefully coordinated and executed with precision.

Construction of Express Highways

Our expressway construction are arterially divided that features two or more traffic lanes in each direction. It is a complex process that requires our thorough planning, design and physical implementation in order to meet the expectations of our clients.

Construction of Buildings

With our elaborate engineering techniques and processes with improvement in contsruction labour, we able to put on sophisticated structures that suit our various clients.

Sand Blasting of Metalic Tanks

Blasting is a surface processing method in which countless abrasive particles are sprayed, thus colliding with the workpiece to roughen, grind, or polish the surface.

Blasting is generally a dry process.

Electricity Generation Using Hydro Power

Hydropower is a sustainable energy source that utilizes the movement of water to generate electricity.

Hydroelectric facilities convert the potential energy of water stored in reservoirs into mechanical energy. This mechanical energy is also referred to as kinetic energy. When water flows through the dam, its kinetic energy is harnessed to rotate a turbine.

This turbine's mechanical energy is then transformed into electrical energy by the generator.

Subsequently, this electrical energy undergoes various transmission processes before it is delivered to you.

Procurement & Logistics

Our Procurement and Logistics Division is dedicated to enhancing the sustainability of our clients. This commitment is at the heart of our operations and is steadily gaining traction. Our focus on sustainability encompasses our supply chain initiatives, addressing environmental concerns, waste reduction, risk management, and ongoing improvements. We specialize in procuring essential resources for various businesses and organizations:

Food Items:

Our Food Procurement and Logistics services involve the careful planning, execution, and oversight of the entire process of food sourcing and storage, ensuring a seamless journey from producers to our clients (the end consumers). This includes our dedicated team managing the logistics of food supply, adhering to stringent food safety standards and maintaining quality, all while delivering in the most efficient and cost-effective manner.

Engineering Machines

Our team, originating from the Procurement and Logistics Division, is dedicated to harnessing the potential of renewable energy through innovative logistics solutions. By 2025, we anticipate a significant advancement: renewable energy will play a crucial role in powering our nation, as well as contributing to the energy landscape across Africa and beyond. As we move towards a sustainable future, the demand for swift and efficient delivery of eco-friendly technology components is paramount.

Safety Gears & Wears

The role of personal protective equipment (PPE) is to minimize the risk of employee exposure to dangers when engineering safety measures and administrative protocols are impractical or insufficient to mitigate these threats to acceptable standards. PPE is essential in environments where hazards are present. However, it has a critical limitation as it does not eradicate the hazard at its source, potentially leaving employees vulnerable if the gear fails.

Get In Touch With Us

We're here for you, let's discuss your next project

33Garrison Street, Freetown, Sierra Leone, West AfricaMon - Fri

08:00 AM -05:00PM+23278545411 +23276452001 +23278249143Select...

Portfolio

Services

About

Contact

Phone: +23278545411 +23276452001 +23278249143

Email: charteredengineeringcec@

Terms of Use

Privacy Policy

ubscribe to Our Newsletter

Proudly Chartered Engineering & Calibration Company